What are LVL Formwork Beams and How are They Manufactured?

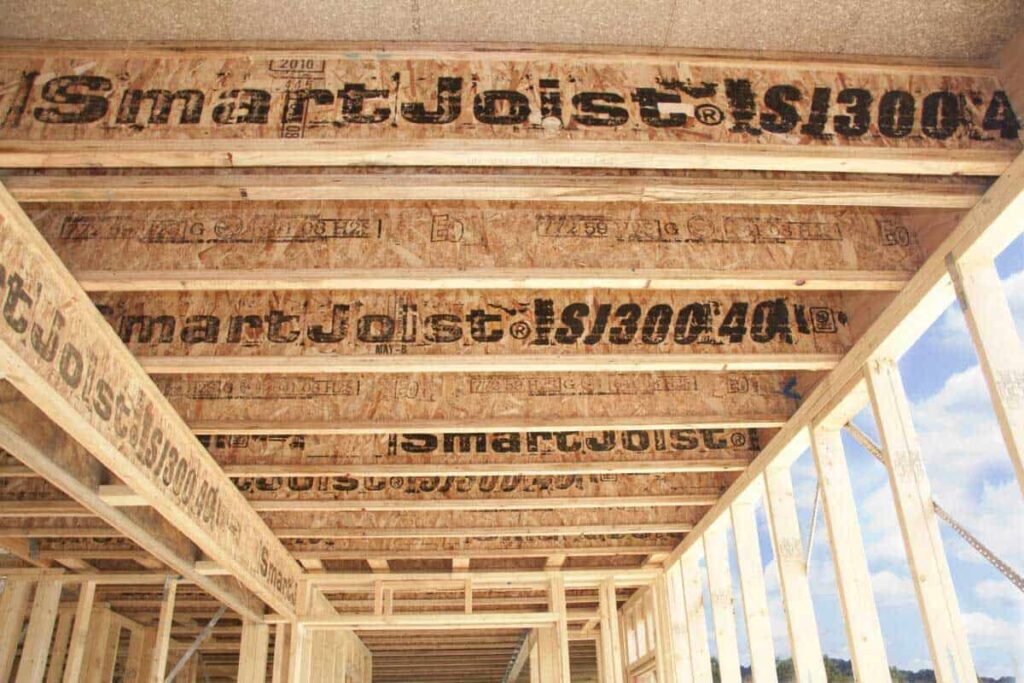

Laminated Veneer Lumber (LVL) formwork beams are engineered wood products designed to support heavy loads in residential and commercial construction projects. These structural components serve as load-bearing elements in floors, roofs, and walls, offering reliable performance where traditional timber might fall short.

The Manufacturing Process of LVL Formwork Beams

The composition centres on thin wood veneers—typically 3mm thick—bonded together using high-strength adhesives under heat and pressure. Each veneer layer contributes to the beam’s structural integrity, creating a product far stronger than the sum of its parts. The manufacturing process transforms renewable timber resources into precision-engineered building materials.

- Raw logs are rotary-peeled to produce continuous veneer sheets

- Veneers undergo drying to achieve optimal moisture content (8-12%)

- Adhesive application occurs under controlled conditions

- Layers stack with grain direction aligned

- High-pressure pressing bonds the assembly permanently

- Precision cutting produces beams to exact specifications

How LVL Differs from Other Wood Products

Grain alignment is a defining advantage of formwork LVL, setting it apart from conventional wood products. In formwork LVL, all veneer layers run parallel to the beam’s length, concentrating strength along the primary load-bearing axis. This engineered parallel grain orientation maximises bending resistance and mitigates the natural weaknesses found in solid timber, such as knots or growth irregularities, delivering consistent structural reliability across demanding formwork applications.

The Advantages of Engineered Wood Process

Traditional lumber manufacturing relies on sawing logs into dimensional pieces, accepting natural variations in grain pattern, density, and moisture content. This approach produces inconsistent strength characteristics between individual boards.

The engineered wood process eliminates these variables, delivering uniform performance across every beam. Each LVL beam structure meets predictable load ratings, allowing engineers to specify materials with confidence rather than building in safety margins to compensate for natural timber variability.

Why Should Builders Prefer LVL Formwork Beams Over Traditional Lumber?

LVL formwork beams deliver significantly higher strength-to-weight ratios than traditional lumber, making them the superior choice for demanding structural applications. The engineered nature of LVL vs traditional lumber means builders can span greater distances with smaller beam sizes whilst maintaining safety margins.

What Strength Advantages Do LVL Beams Offer?

LVL beams consistently outperform conventional timber in load-bearing capacity by 50-70%. The parallel grain alignment throughout every layer eliminates the weak points found in natural wood, where knots, splits, and grain irregularities compromise structural integrity.

Key strength advantages include:

- Load capacity up to 2,800 pounds per square inch in bending

- Uniform strength across the entire beam length

- Predictable performance under stress

- Ability to support concentrated loads without additional reinforcement

The manufacturing process removes natural defects that weaken traditional lumber. Each veneer layer undergoes quality inspection before bonding, ensuring only premium wood contributes to the final product’s strength.

How Does Dimensional Stability Benefit Construction Projects?

LVL beams maintain their shape and dimensions throughout their service life, unlike traditional lumber which commonly warps, twists, or shrinks. This dimensional stability stems from the cross-laminated veneer structure that counteracts natural wood movement caused by moisture fluctuations.

Builders experience fewer callbacks and warranty claims when using LVL beams. The beams remain straight and true, preventing:

- Sagging floors and ceilings

- Misaligned door and window frames

- Cracked plasterwork from structural movement

- Squeaky floors caused by timber shrinkage

Traditional lumber can shrink up to 8% across the grain as it dries, creating gaps and structural issues. LVL beams exhibit less than 1% dimensional change under similar conditions.

What Makes LVL Beams Resistant to Moisture and Pests?

The adhesive bonding process creates a moisture-resistant barrier between veneer layers, significantly reducing water absorption compared to solid timber. LVL beams treated with appropriate preservatives resist fungal decay and insect damage that commonly plague traditional lumber in damp environments.

What Key Factors Should Be Considered When Choosing an LVL Beam?

Choosing LVL beam specifications begins with understanding your project’s structural demands. The right selection depends on matching beam characteristics to specific construction requirements, architectural design, and long-term performance expectations.

How Do Project-Specific Needs Determine Beam Selection?

Load-bearing requirements form the foundation of any beam selection process. Calculate the total weight the beam must support, including permanent fixtures (dead loads) and variable weights like occupants and furniture (live loads). Span length—the distance between support points—directly influences the beam dimensions needed. A 6-metre span supporting a residential floor requires different specifications than a 3-metre span carrying the same load.

Building codes and local regulations establish minimum standards for structural elements. Verify compliance requirements early in the planning phase to avoid costly modifications later. Seismic zones, wind load ratings, and snow accumulation factors may mandate specific beam grades or installation methods.

What Architectural Considerations Affect Beam Choice?

Ceiling height restrictions often dictate maximum beam depth. A shallow beam profile maintains headroom in basements or beneath low ceilings, whilst deeper beams provide greater strength for open-concept designs. Exposed beams in visible areas may require aesthetic treatments or specific finishes that influence material selection.

Integration with other building systems matters significantly. HVAC ductwork, plumbing runs, and electrical conduits must route around or through structural members. Coordinate beam placement with mechanical drawings to prevent conflicts during installation. Some projects benefit from pre-drilled LVL beams that accommodate service penetrations without compromising structural integrity.

Why Does Beam Size Selection Matter?

Beam size selection directly impacts structural performance and installation efficiency. Width options typically range from 45mm to 600mm, whilst depths span from 90mm to 450mm. Wider beams distribute loads across greater bearing surfaces, reducing point stress on supporting walls or columns.

Standard residential applications commonly use:

- 45mm x 240mm for light-duty floor joists

- 90mm x 300mm for medium-span floor beams

- 135mm x 400mm for heavy-load headers and ridge beams

How is the Load Capacity of an LVL Beam Calculated?

LVL beam load calculation begins by determining the total loads the beam must support, which include both dead loads (permanent structural weight) and live loads (temporary or movable weights). Dead loads encompass the weight of the beam itself, flooring materials, ceiling finishes, and any permanently attached fixtures. Live loads account for occupants, furniture, equipment, and environmental factors such as snow accumulation on roofs.

To accurately assess these loads, builders must reference local building codes and standards, which specify minimum load requirements based on the structure’s intended use. Residential floor systems typically require live loads of 1.9 kPa (40 psf), whilst commercial spaces may demand significantly higher values depending on occupancy classification.

What Role Do Manufacturer Specifications Play?

Manufacturer specifications provide critical allowable stress limits that govern safe beam performance. These specifications detail the maximum bending stress (Fb), shear stress (Fv), and modulus of elasticity (E) values specific to each LVL product. Reputable manufacturers test their products according to standards such as BS EN 14374 or ASTM D5456, publishing load tables that simplify beam selection.

The allowable bending stress typically ranges from 2,800 to 3,200 psi for standard LVL products, though values vary based on wood species and manufacturing processes. Designers must apply appropriate safety factors and adjustment factors for load duration, moisture conditions, and temperature exposure when using these specifications.

How Do You Calculate Moment of Inertia?

Moment of inertia (I) quantifies a beam’s resistance to bending and directly influences load capacity calculations. For rectangular LVL beams, the formula is:

I = (b × h³) / 12

Where:

- b = beam width in millimetres

- h = beam depth in millimetres

A 45mm wide by 300mm deep LVL beam yields a moment of inertia of 101,250,000 mm⁴. Doubling the depth to 600mm increases the moment of inertia eightfold to 810,000,000 mm⁴.

What Safety Precautions are Necessary When Handling and Installing LVL Beams?

Safety when handling and installing LVL beams starts with understanding that these engineered products have specific challenges due to their heavy weight and large size. A standard LVL beam measuring 3.5 inches by 14 inches and spanning 20 feet can weigh over 150 pounds, which means that multiple workers and mechanical assistance are needed for safe movement and positioning.

How Should Teams Handle Heavy LVL Beams?

Using proper lifting techniques is crucial for safely handling LVL beams. Workers should keep their backs straight while bending at the knees and hold the beam close to their bodies during lifts. For beams longer than 12 feet, teams of at least two people should handle them, and additional support is necessary for spans exceeding 20 feet.

To further reduce the risk of injuries, mechanical aids can be used:

- Forklift attachments with extended forks for long spans

- Crane systems with properly rated slings for vertical lifts

- Beam trolleys for horizontal movement across job sites

- Rolling carts with secure strapping for ground-level transport

It’s equally important to pay attention to storage protocols. Beams should be stacked on level, dry surfaces with adequate support every 4-6 feet to prevent sagging. Spacers should be placed between layers to allow air circulation and prevent moisture accumulation.

What Installation PPE Protects Workers Most Effectively?

Personal protective equipment (PPE) is the last line of defence against hazards on construction sites. Hard hats with chin straps protect against falling objects and accidental head strikes against overhead beams. Safety glasses with side shields guard eyes from wood splinters and dust particles generated during cutting or drilling operations.

Essential installation PPE includes:

- Steel-toed boots with slip-resistant soles for secure footing on elevated surfaces

- Work gloves with reinforced palms for grip and splinter protection

- Fall protection harnesses when working above 2 metres

- Hearing protection during power tool operations

- Dust masks rated N95 or higher for cutting and sanding tasks

Hand protection requires special consideration. It’s important to choose gloves that provide a balance between grip security and tactile sensitivity, allowing workers to feel fasteners and connections while still protecting against sharp edges and rough surfaces.

Why Do Regular Inspections Matter?

How Does Cost Influence the Selection of the Right LVL Formwork Beam?

LVL beam cost analysis reveals that upfront pricing typically exceeds traditional timber by 20-40%, yet this initial investment masks the true economic picture. A standard LVL formwork beam might cost £45-£75 per linear metre, whilst comparable dimensional timber ranges from £30-£50 per linear metre. The price differential stems from the sophisticated manufacturing process and superior engineering properties that LVL beams deliver.

What Makes Up the Initial Investment?

The purchase price reflects multiple value components beyond raw materials:

- Manufacturing precision through computer-controlled layering and bonding processes

- Quality assurance testing ensuring consistent structural performance

- Extended span capabilities reducing the need for additional support structures

- Customisation options allowing precise dimensional specifications

- Certified performance ratings backed by engineering data and warranties

Builders often discover that fewer LVL beams achieve the same structural goals as multiple traditional timber pieces. A single 300mm deep LVL beam can replace two or three conventional timber beams, offsetting the higher per-unit cost through reduced material quantities and simplified installation labour.

How Do Long-Term Savings Alter the Economic Equation?

Long-term savings emerge through multiple channels that traditional timber cannot match. LVL beams maintain dimensional stability for decades, eliminating costly callbacks for sagging floors or cracked plaster caused by warping timber. Property owners avoid the £500-£2,000 repair bills that frequently arise from structural lumber failures within 5-10 years.

Maintenance requirements drop dramatically with LVL formwork beams. Traditional timber demands regular inspections, potential treatments for pest infestations, and moisture-related interventions. LVL beams resist these common degradation factors, cutting maintenance expenses by an estimated 60-75% over a 25-year lifespan.

Insurance premiums may decrease when LVL beams form part of the structural system. Their fire-resistant treatments and predictable performance characteristics appeal to underwriters assessing risk profiles. Some builders report premium reductions of 5-12% on commercial projects featuring engineered wood products.

Does Project Scale Impact Cost Effectiveness?

Larger construction projects amplify the benefits of LVL formwork beams due to economies of scale. As project size increases, fixed costs associated with design, transportation, and installation are spread over a larger number of units.

This phenomenon enhances the cost-effectiveness of using engineered wood products like LVL in substantial builds where traditional timber may still be prevalent. It becomes crucial for builders to evaluate not just immediate expenses but also long-term returns on investment when determining material selections for expansive undertakings.

In summary, while upfront costs may favour conventional timber options initially, a comprehensive assessment encompassing future savings potential reveals a compelling case for choosing LVL formwork beams—especially in large-scale constructions where their inherent advantages can be fully realised.

How Do You Ensure Optimal Results with Your LVL Beam Selection?

Selecting the right LVL formwork beam demands careful alignment between your project’s structural requirements and the beam’s capabilities. The benefits of correct LVL selection extend far beyond immediate construction needs, influencing long-term building performance, safety standards, and cost efficiency throughout the structure’s lifespan.

Every construction project presents unique challenges that require tailored solutions. Your beam choice must account for specific load-bearing demands, span requirements, environmental conditions, and architectural constraints. A residential renovation requires different specifications compared to a commercial development, whilst moisture-prone environments necessitate enhanced treatment options that dry climates may not demand.

The Definitive Guide to Choosing the Right LVL Formwork Beam centres on understanding these interconnected factors:

- Structural precision: Match beam dimensions and load capacity to calculated requirements

- Environmental adaptation: Select appropriate treatments for moisture, fire, or pest resistance based on location

- Budget optimisation: Balance upfront investment against lifecycle durability and maintenance savings

- Safety compliance: Verify manufacturer specifications meet or exceed local building codes

- Sustainability goals: Choose products from certified sustainable forestry programmes when environmental impact matters

Professional consultation with structural engineers proves invaluable when navigating complex specifications or unusual architectural designs. Their expertise ensures your selection meets regulatory standards whilst optimising material efficiency. Documentation of your selection process, including load calculations and manufacturer certifications, provides essential records for inspections and future maintenance planning.

The right LVL formwork beam transforms from a simple building component into a strategic investment. Proper selection delivers structural reliability, reduces long-term maintenance burdens, and supports sustainable construction practices. Your attention to project-specific requirements during the selection phase establishes the foundation for successful construction outcomes that endure for decades.

FAQs (Frequently Asked Questions)

What are LVL formwork beams and how are they manufactured?

LVL formwork beams, or Laminated Veneer Lumber beams, are engineered wood products composed of bonded wood veneers with grains aligned and layered to enhance strength and consistency. Unlike traditional lumber, LVL beams undergo a manufacturing process that involves bonding thin wood veneers under heat and pressure, resulting in superior quality and uniformity ideal for construction.

Why should builders prefer LVL formwork beams over traditional lumber?

Builders prefer LVL formwork beams due to their superior strength, higher load-bearing capacity, and excellent dimensional stability. These beams resist warping, twisting, and shrinking better than traditional lumber. Additionally, LVL beams offer enhanced moisture and pest resistance and contribute to eco-friendly building practices through sustainable forestry.

What key factors should be considered when choosing an LVL formwork beam?

When selecting an LVL formwork beam, consider project-specific requirements such as load capacity and span length, architectural design considerations, and appropriate beam size including width and depth. It’s also important to evaluate material quality factors like wood species density and available treatment options to ensure optimal performance.

How is the load capacity of an LVL beam calculated?

Calculating the load capacity of an LVL beam involves assessing total expected loads—including live and dead loads—referring to manufacturer specifications for allowable stress limits, and computing the moment of inertia based on the beam’s dimensions. These steps ensure the beam can safely support structural demands.

What safety precautions are necessary when handling and installing LVL beams?

Handling and installing LVL beams require proper techniques due to their weight and size. Personal protective equipment (PPE) such as gloves, helmets, and safety boots should be worn during installation. Regular inspections for moisture damage or pest infestations are crucial to maintain structural integrity and ensure safety on site.

How does cost influence the selection of the right LVL formwork beam?

While the initial purchase price of LVL formwork beams may be higher than traditional lumber, their durability and reduced maintenance needs often lead to long-term savings. Evaluating both upfront costs and potential lifecycle benefits helps in selecting the most cost-effective beam option for your construction project.

See more about: 5 Essential Tips for Working with formply on Your Next Concrete Project